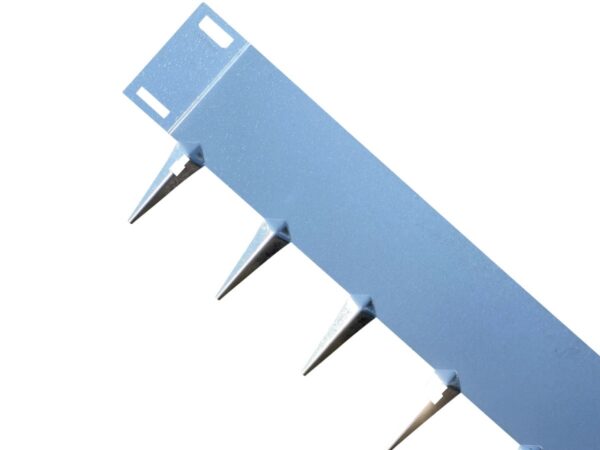

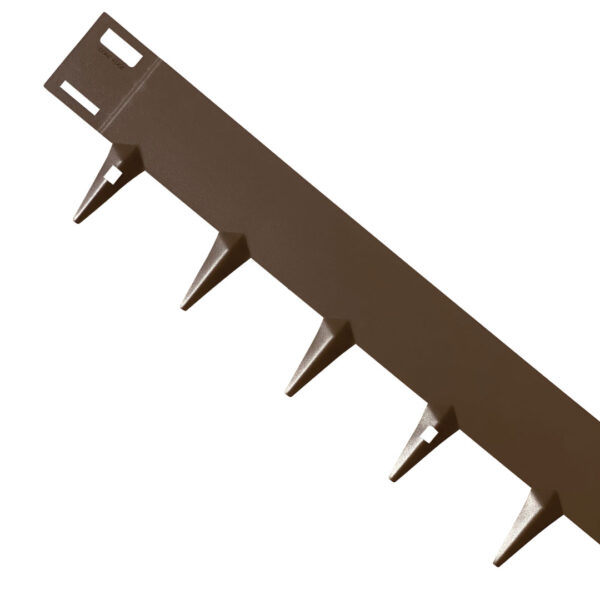

Each type of border, with the exception of the patinated steel (Cor-ten), has a 20-micron layer of zinc. The black (RAL 9005) edging has a 110-micron UV-resistant powder coating that prevents discolouration and forms a durable, radiation-resistant coating, good for a guaranteed life of more than 20 years. The Cor-ten border takes on a rust-like appearance when exposed to the elements of nature. The steel oxidizes and this protective layer significantly slows the rate of future corrosion. The anchoring pins contain a unique fold in the middle, strengthening the ground anchor and making the border ideal for use in heavier soil. In case of loose soil, an optional 300mm pin can be chosen to ensure stability. This accessory is available separately.

Core Edge powered by ECCO

The CORE Edge powered by ECCO guards are made of 1.6mm mild steel and sufficiently strong for lawn mowers and light vehicles. These fexible, steel border edges can be quickly installed without special tools. Easy to install in straight lines and curved shapes or bend on-site into corners.

Find your distributor, price request or product question?

How many buckets of joint filler do I need?

Enter the dimensions below and we will calculate how many buckets you need.

- Easy installation

- Weatherproof

- Strong

- Lawn and border edges

- Finishing of paths and terrace

- Flower bed or vegetable garden

Flexible steel edging!

1.Prepare the area you would like to install the edging. Make sure the ground is relatively soft. If not, loosen up the ground with a flat spade or pickaxe to make the edging easier to install. |

|

2.Once the ground is prepped, begin by placing your first piece of CORE EDGE into the ground, up close to the edge you have formed. Ensure the edging is facing the correct way – with the logo facing outwards. |

|

3.The best way to drive the edging into the ground is by using a block of wood and a hammer/mallet. The block of wood ensures the top of the edging doesn’t get damaged and makes installation safer. |

|

4.Once the first piece is tapped into the ground, you can attach the second piece by securing them together using the large tab at the top of each piece of edging. |

|

5.After securing the edging at the top, take a pair of thing nose pliers and then bend the tabs at the bottom to fully secure the two pieces of CORE EDGE together. |

|

6.Repeat steps 4 and 5. If you encounter particularly soft ground, our 300mm extension pins can be used. Take the clip and pop it through the opening in the spike first. |

|

7.Once the clip is secured, take the 300mm pin and place it through the hole and hold in place. Take your hammer/mallet and tap it through the opening of the clip. Hammer the pin all the way down to the top of the clip. The pin ensures additional stability. |

|

8.The finished result will leave a crisp and neat finish to your garden borders. Here is a straight line edge, but the edging can be curved or bent into 90 degree angles for corners – see for yourself by scanning the QR code to the video above. |

|

- Material: Flexible steel

- Material thickness: 1.6mm

- Overall length: 1075mm

- Usable length: 1000mm

- Number per package: 5 borders (5m total)